With the business philosophy of localization and internationalization and a serious and responsible working attitude, the company continues to improve the company's service system and improve product quality...

With the business philosophy of localization and internationalization and a serious and responsible working attitude, the company continues to improve the company's service system and improve product quality...

With the business philosophy of localization and internationalization and a serious and responsible working attitude, the company continues to improve the company's service system and improve product quality...

With the business philosophy of localization and internationalization and a serious and responsible working attitude, the company continues to improve the company's service system and improve product quality...

With the business philosophy of localization and internationalization and a serious and responsible working attitude, the company continues to improve the company's service system and improve product quality...

With the business philosophy of localization and internationalization and a serious and responsible working attitude, the company continues to improve the company's service system and improve product quality...

With the business philosophy of localization and internationalization and a serious and responsible working attitude, the company continues to improve the company's service system and improve product quality...

With the business philosophy of localization and internationalization and a serious and responsible working attitude, the company continues to improve the company's service system and improve product quality...

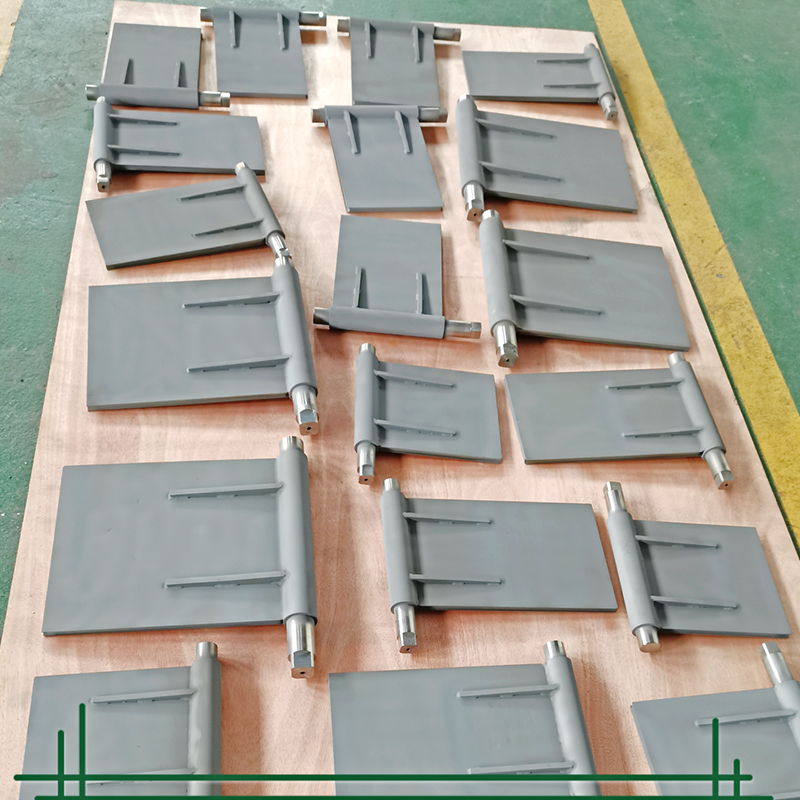

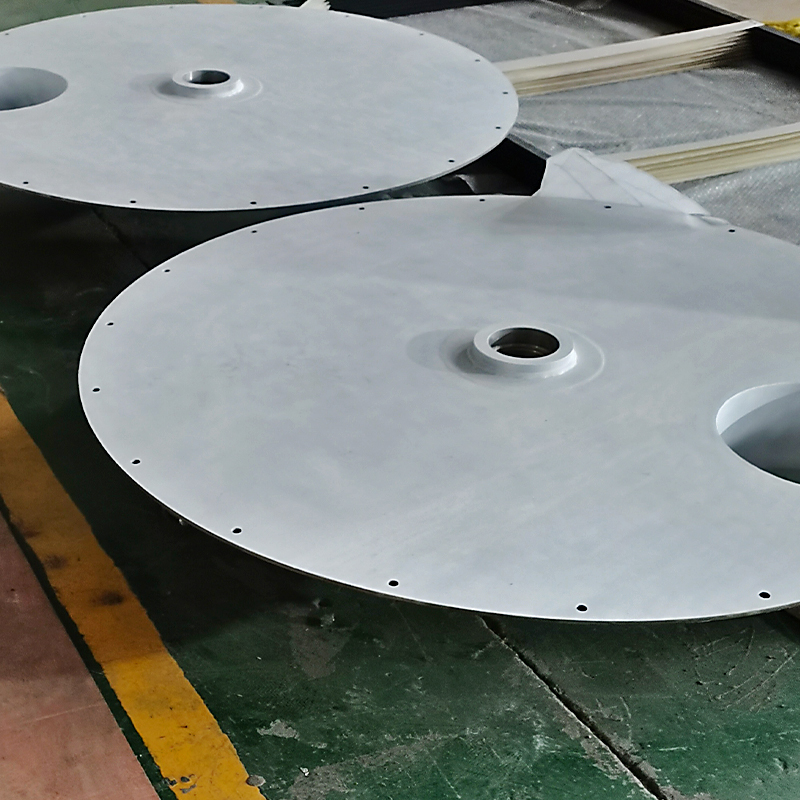

Provide overall solutions for spraying services

Lean manufacturing perfect service

The valve stem is sprayed with PTFE (polytetrafluoroethylene) for the following purposes: 1. reduce friction coefficient: PTFE has a low friction coefficient. Spraying on the valve rod can make the valve rod smoother in the process of movement, reduce friction with other parts, reduce the operating torque, make the opening and closing of the valve more flexible, reduce wear, and extend the servic

Lithium battery equipment sprayed with tungsten carbide has the following characteristics: 1. High hardness and wear resistance Tungsten carbide has high hardness, and spraying it on lithium battery equipment can effectively improve the wear resistance of the equipment surface. For example, in the production process of lithium batteries, some components of the equipment, such as the scrap

Spraying Teflon on the lithium battery silo can significantly improve the performance of the silo, and has good effects in improving production efficiency, ensuring product quality and reducing maintenance costs, as follows: 1. improve production efficiency Promote material flow: the low friction coefficient of Teflon can make the flow of lithium battery materials in the silo more smooth,

Lithium battery equipment plasma sprayed aluminum oxide coating has many advantages, mainly including the following points: 1. good insulation performance: the alumina coating has high resistivity, which can effectively prevent the current leakage inside the battery, avoid battery short circuit, and improve the safety and stability of the battery. This is very important for the reliable operation

The agitator is sprayed with ETFE (ethylene tetrafluoroethylene copolymer) anti-corrosion coating, which has the following characteristics: 1. good corrosion resistance Strong acid and strong alkali environment: ETFE coating has good resistance to strong acid and strong alkali such as sulfuric acid, hydrochloric acid, nitric acid, sodium hydroxide, etc., can maintain stability in these co

Spraying ECTFE on pharmaceutical three in one equipment is a surface coating technology, as follows: 1. Material properties of ECTFE: ECTFE is an ethylene chlorotrifluoroethylene copolymer, which is copolymerized with chlorofluoroethylene and trifluoroethylene. It has excellent chemical stability, can resist the erosion of strong acid, alkali, organic solvent and other chemical substances, and al

We found through the later use process that we can find that the metal materials that have been sprayed by halar will have a relatively large improvement in the service life and applicability

With the continuous improvement of halar spraying technology, the application range has also changed from industrial production to daily life.

In fact, from the name, we found that it is naturally impossible to be ordinary spray paint. Whether it is the selection of spray materials

The valve stem is sprayed with PTFE (polytetrafluoroethylene) for the following purposes: 1. reduce friction coefficient: PTFE has a low friction coefficient. Spraying on the valve rod can make the valve rod smoother in the process of movement, reduce friction with other parts, reduce the operating torque, make the opening and closing of the valve more flexible, reduce wear, and extend the servic

Lithium battery equipment sprayed with tungsten carbide has the following characteristics: 1. High hardness and wear resistance Tungsten carbide has high hardness, and spraying it on lithium battery equipment can effectively improve the wear resistance of the equipment surface. For example, in the production process of lithium batteries, some components of the equipment, such as the scrap

Spraying Teflon on the lithium battery silo can significantly improve the performance of the silo, and has good effects in improving production efficiency, ensuring product quality and reducing maintenance costs, as follows: 1. improve production efficiency Promote material flow: the low friction coefficient of Teflon can make the flow of lithium battery materials in the silo more smooth,

Lithium battery equipment plasma sprayed aluminum oxide coating has many advantages, mainly including the following points: 1. good insulation performance: the alumina coating has high resistivity, which can effectively prevent the current leakage inside the battery, avoid battery short circuit, and improve the safety and stability of the battery. This is very important for the reliable operation

Suzhou xinrongfa metal products Co., Ltd. was founded in 2008 as Suzhou Xinxin precious metal products Co., Ltd. It is an enterprise integrating Teflon, tungsten carbide and alumina coating spraying. The company is located in Wujiang District, Suzhou City, Jiangsu Province (the hinterland of the Yangtze River Delta), close to Shanghai Hongqiao 8 ㎞, Hangzhou 1.5 hours away, Wuxi Sunan airport 60 kilometers away, 3 ㎞, g15w2 Changjia Expressway 1 ㎞, g15w Changtai Expressway 6 ㎞, close to the beautiful scenic spot Taihu lake....

productapplicationContact us